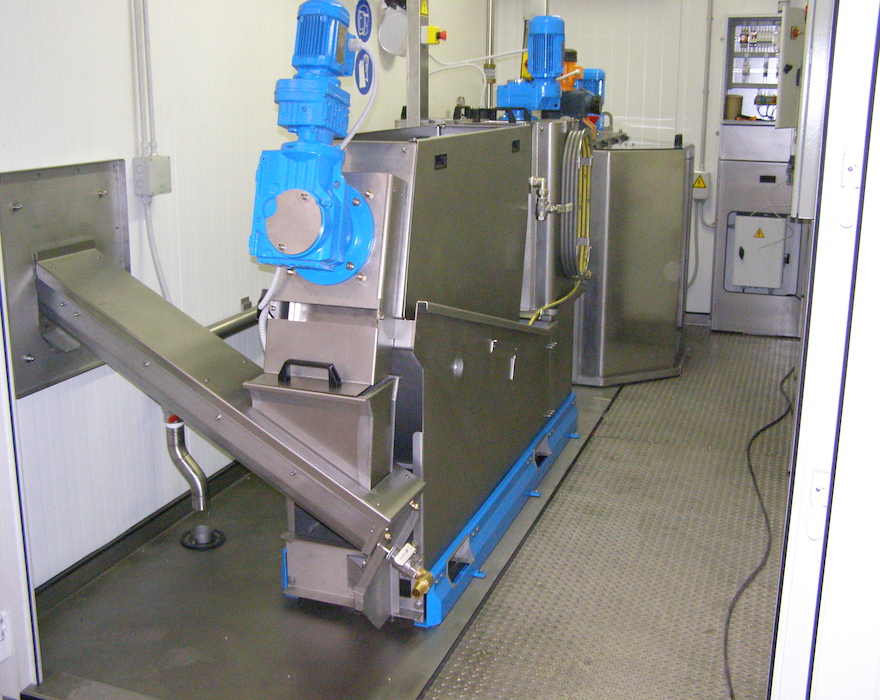

The unit is equipped with two mixing chambers

- Chamber with a fast mixer for pH correction needs

- Chamber for mixing flocculant and sludge, designed with a special mixer

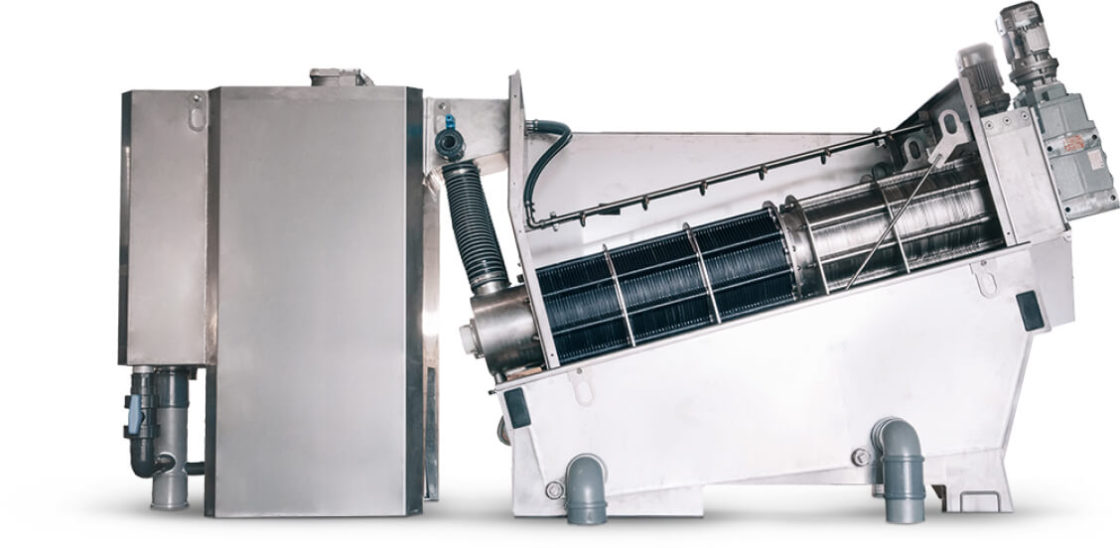

FDS is structured with a filter element that consists of two types of rings: fixed ring and moving ring, and a screw that thrusts the filter element and transfers and pressurizes the sludge.

The gaps between the rings and the screw pitch are designed to gradually get narrower towards the direction of the sludge cake oulet and the inner pressure of the filter element increases due to the volume compression effect, which thickens and dewaters the sludge.

Useful during Pilot Tests to identify the right flocculant, demonstrate operational results, and determine the suitable size of dewatering press for specific needs

Short-term solution during equipment maintenance

Existing system needs replacement, requiring dewatering during the transition

As portable dewatering systems in areas without installed dewatering systems

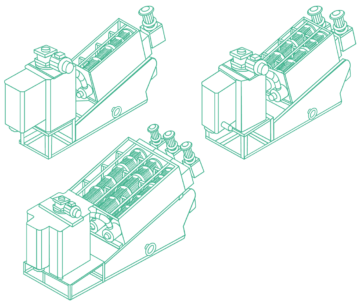

This compact version is designed for use with a category B driver's license. Ideal solution for conducting field tests on selecting flocculants

Mobile coontainers to reach maximum productivty

This version is equiped with bigger screw press with higher performance. Ideal solution for rental services

Advantages:

Integrated liquid Himoloc polymer mixing with static mixerAdvantages:

Is the the process where where destabilized sludge particles are agglomerated in aggregates called flocs

| Overall dimensions (L×W×H) | 4340×1870×2300 mm |

| Total weight | 750 kg |

| Total Power Consumption | 3.0 kW |

| Trailer operable with | Category B drive’s license |

| Control Panel | Siemens PLC, Touch panel |

| Electrical grid | 230/400 V; 3-phase, 50 HZ |

| Type of sludge | Municipal and Industrial | |||

| Sludge concentration | 0.2% | 1% | 2% | 5% |

| Flow rate. m3/h | 4.5 | 1.3 | 1.1 | 0.88 |

| Throughput, kg-DS/h | 8.0 | 13.0 | 44.0 | 90.0 |

| Overall dimensions (L×W×H) | 4920×1930×2300 mm |

| Total weight | 1 545 kg |

| Total Power Consumption | 3.0 kW |

| Trailer operable with | Category B drive’s license |

| Control Panel | Siemens PLC, Touch panel |

| Electrical grid | 230/400 V; 3-phase, 50 HZ |

| Type of sludge | Municipal and Industrial | |||

| Sludge concentration | 0.2% | 1% | 2% | 5% |

| Flow rate. m3/h | 10.0 | 3.0 | 2.5 | 0.88 |

| Throughput, kg-DS/h | 20.0 | 60.0 | 100.0 | 150.0 |

| Type of sludge | Municipal and Industrial | |||

| Sludge concentration | 0.2% | 1% | 2% | 5% |

| Flow rate. m3/h | 20.0 | 6.0 | 5.0 | 0.88 |

| Throughput, kg-DS/h | 40.0 | 120.0 | 200.0 | 300.0 |

| Type of sludge | Municipal and Industrial | ||||

| Sludge concentration | 0.2% | 1% | 2% | 5% | 3% Mixed Raw Sludge |

| Flow rate-MAX. m3/h | 100.0 | 30.0 | 24.0 | 19.0 | 40.0 |

| Throughput, kg-DS/h | 200.0 | 300.0 | 480.0 | 960.0 | 1 230 |

Innovative and unique HIMOLOC technology allows us to manufacture polyacrilamides in water dispersion form, free of solvents, surfactants and mineral oils.

The product appearance is a white milky liquid and once dissolved it became transparent.

Flocculants:

| HIMOLOC | Emulsion products | Powder products | |

| Preparation equipment | simple easy-to-use | complex and complicated to operate | complex and complicated to operate |

| Before Use | No stirring needed | Stirring recommended | Hydroscopic products provoke aggregates |

| Solubility | Complete between 0.1%–5% | Minimum concentration is needed | Loss of perfomance because of uncompleted dissolution |

| Dissolution time | <10 min (almost instantly with static mixer) | >30 min | >60 min |

| Water quality effects in dissolution | NO | YES | YES |

| VOCs Increase | NO | YES | NO |

| Direct application | YES | NO | NO |

| COD & BOD Increase | NO | YES | NO |

| Freezing Temperature | Very low | Low | N/A |

| Shelf life | 9 month | 6 months | 12 months |